TYPES OF CONVEYING EQUIPMENT

- Belt Conveyor

- Screw Conveyor (Auger)

- Drag Chain Conveyors

- Bucket Elevator (Noria)

Among the most common types are belt and chain conveyors. Belt conveyors are used not only for grain but also for heavier materials like root crops, pellets, various feeds, and more. A chain conveyor can easily move large volumes of grain at angles up to 85 degrees, as well as hot materials like ash. The popularity of these conveyors is due to their key advantages:

- Mobility due to the equipment's low weight and compact size

- Ease of operation

- High performance and durability over long periods

- Simple design

- Materials can be easily transported vertically or horizontally to hard-to-reach places.

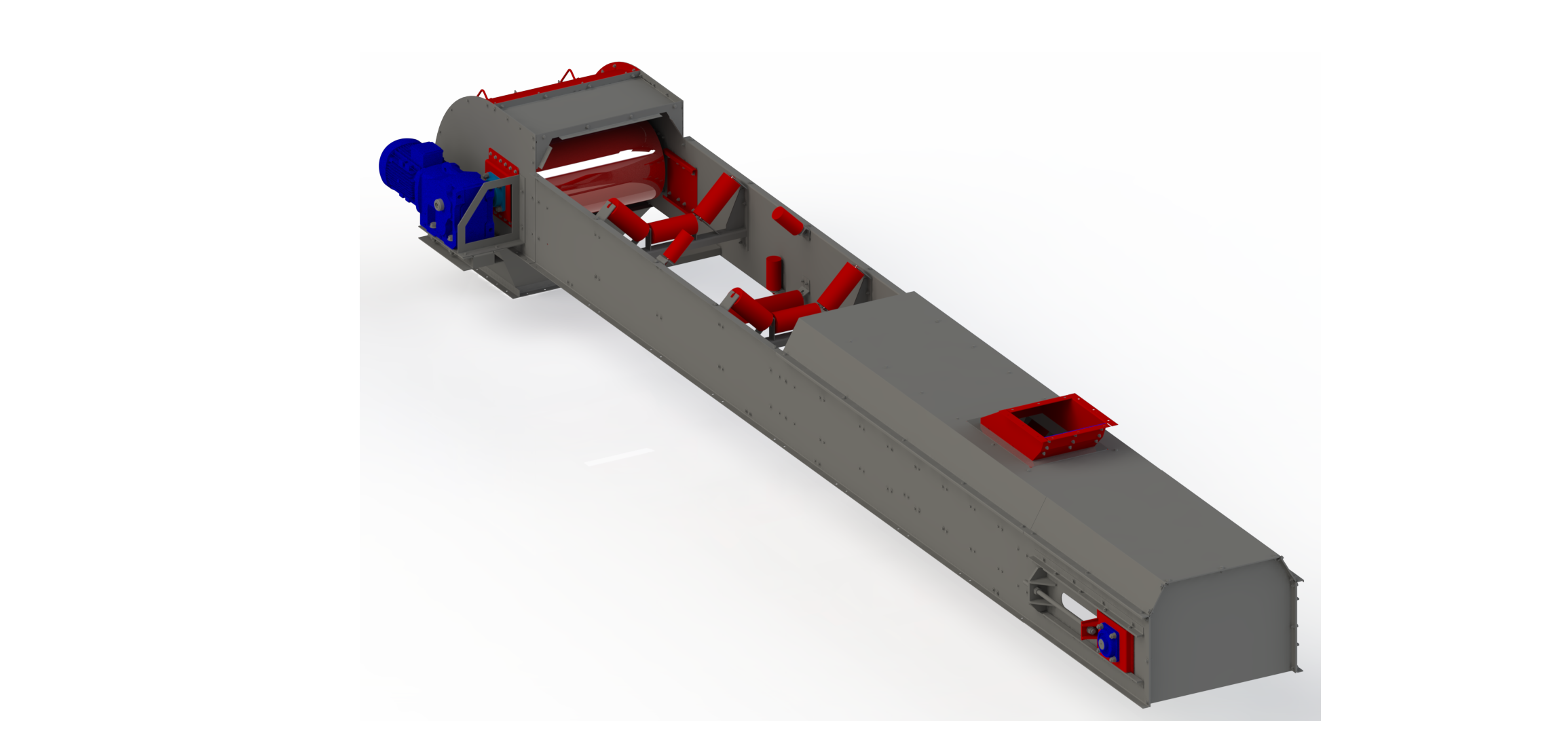

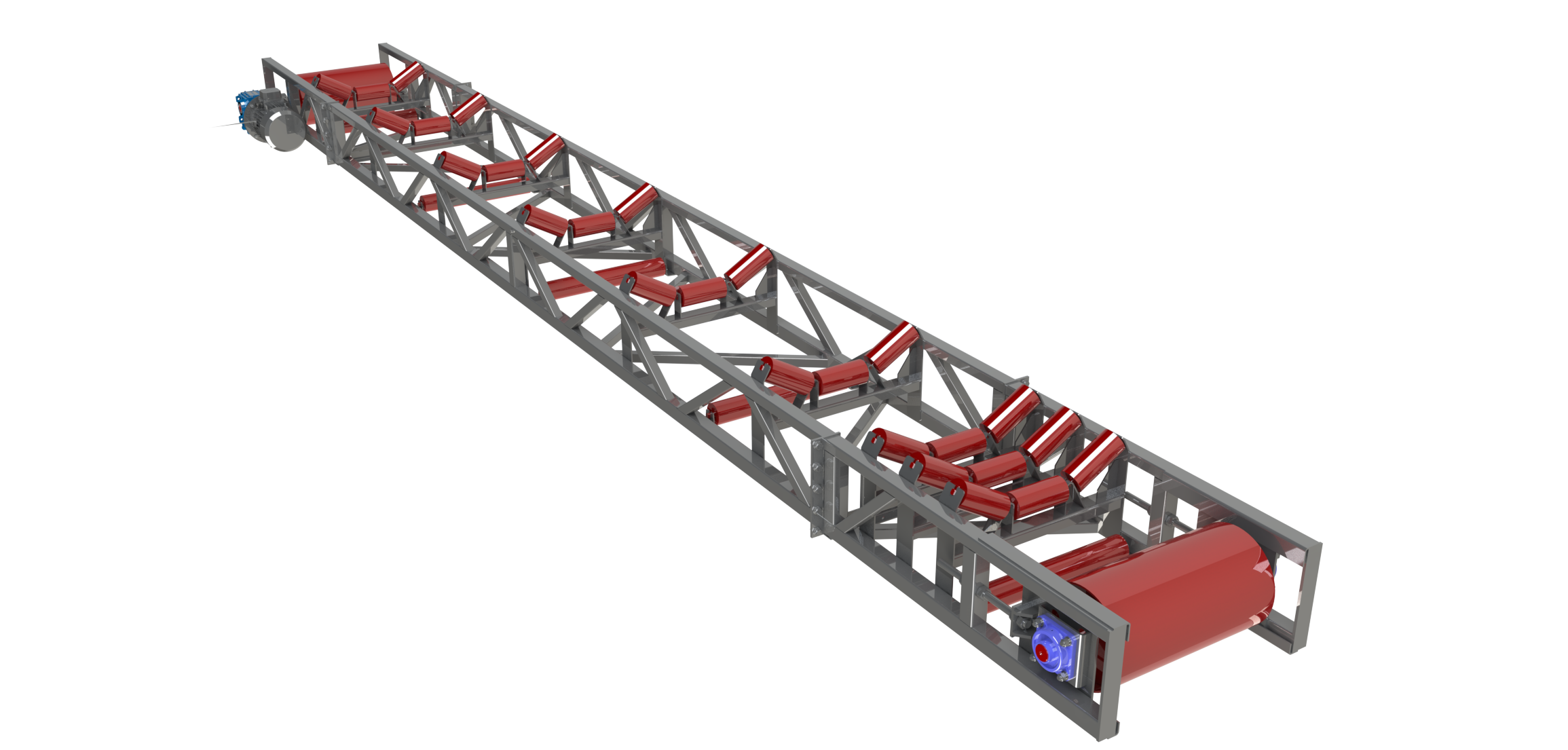

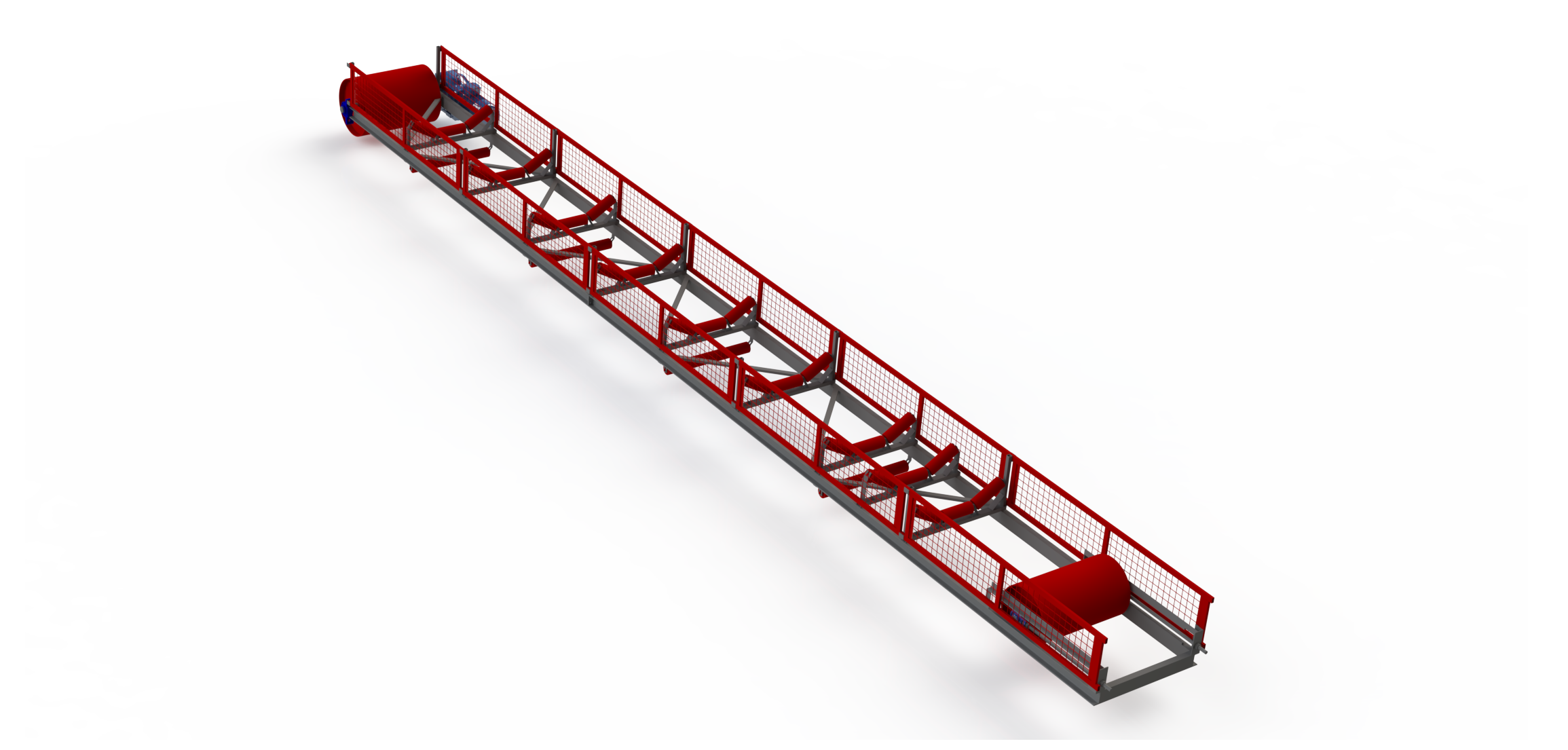

Belt Conveyor

The belt conveyor is frequently used in various industries. It is designed to move grain and other bulk or non-bulk materials over distances of up to 1000 meters. Depending on the model, a belt conveyor can have a capacity of 50 to 1000 tons per hour, including operation at angles of up to 45 degrees.

Belt conveyors move grain gently, without causing damage. They are also convenient for transporting highly dusty materials such as cement, flour, pellets, finely ground feed, and additives. These conveyors are often used in packaging departments to move finished products (cereals, granulated sugar, salt, etc.).

The design is very simple, consisting of a belt and rollers. The belt is self-cleaning, which is convenient for use in large-scale production. A belt conveyor has three sections: tension, drive, and intermediate. The drive section is designed to allow for easy replacement of the shaft or pulley without removing or splitting the belt.

Many models of grain belt conveyors use an automated mobile tripper, which is controlled by a remote. The conveyor belt can be made of vinyl, silicone, rubber, urethane, or PVC. Its surface can be rough, textured, or smooth, and is selected based on the conveyor's specific application.

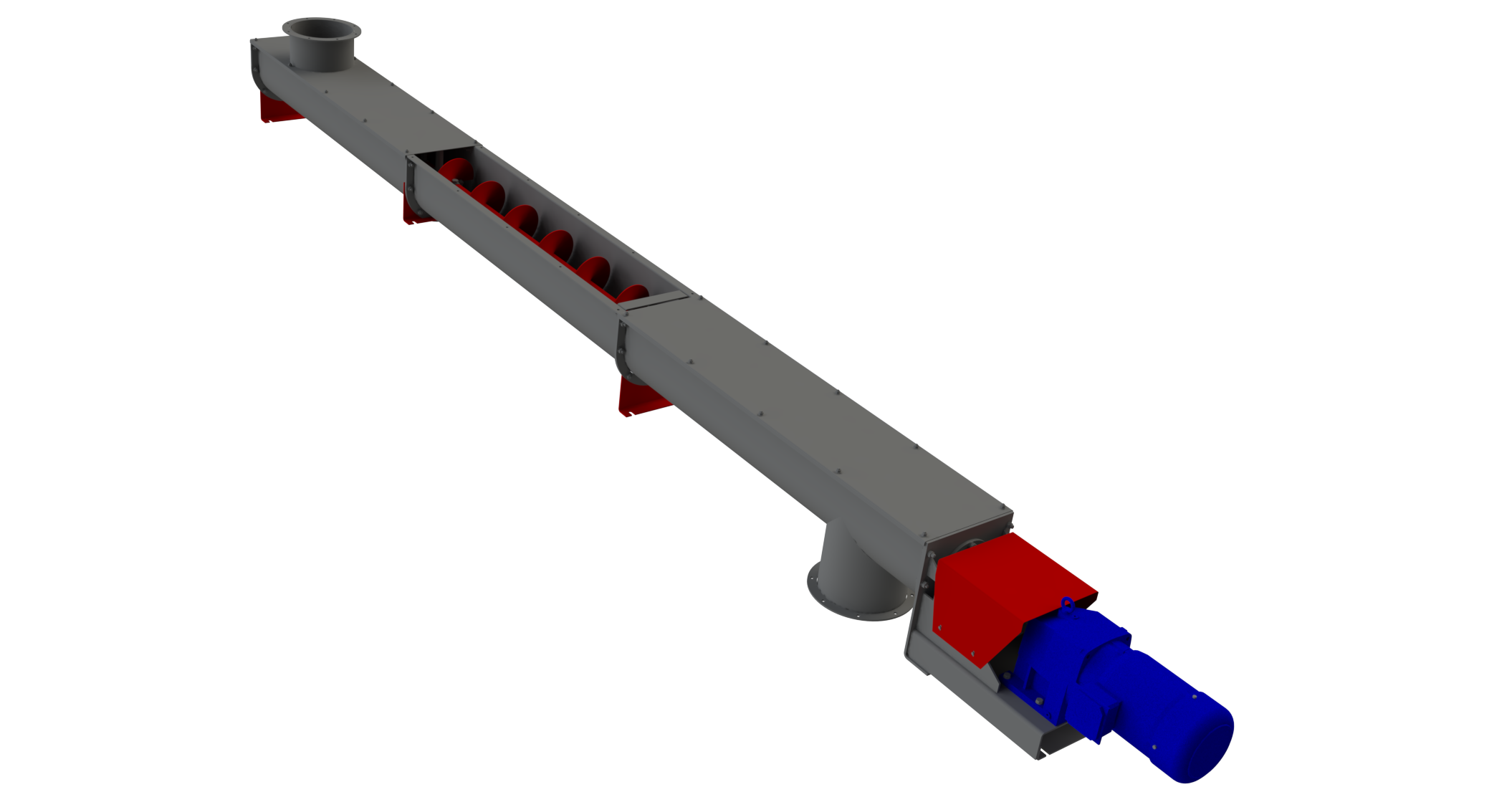

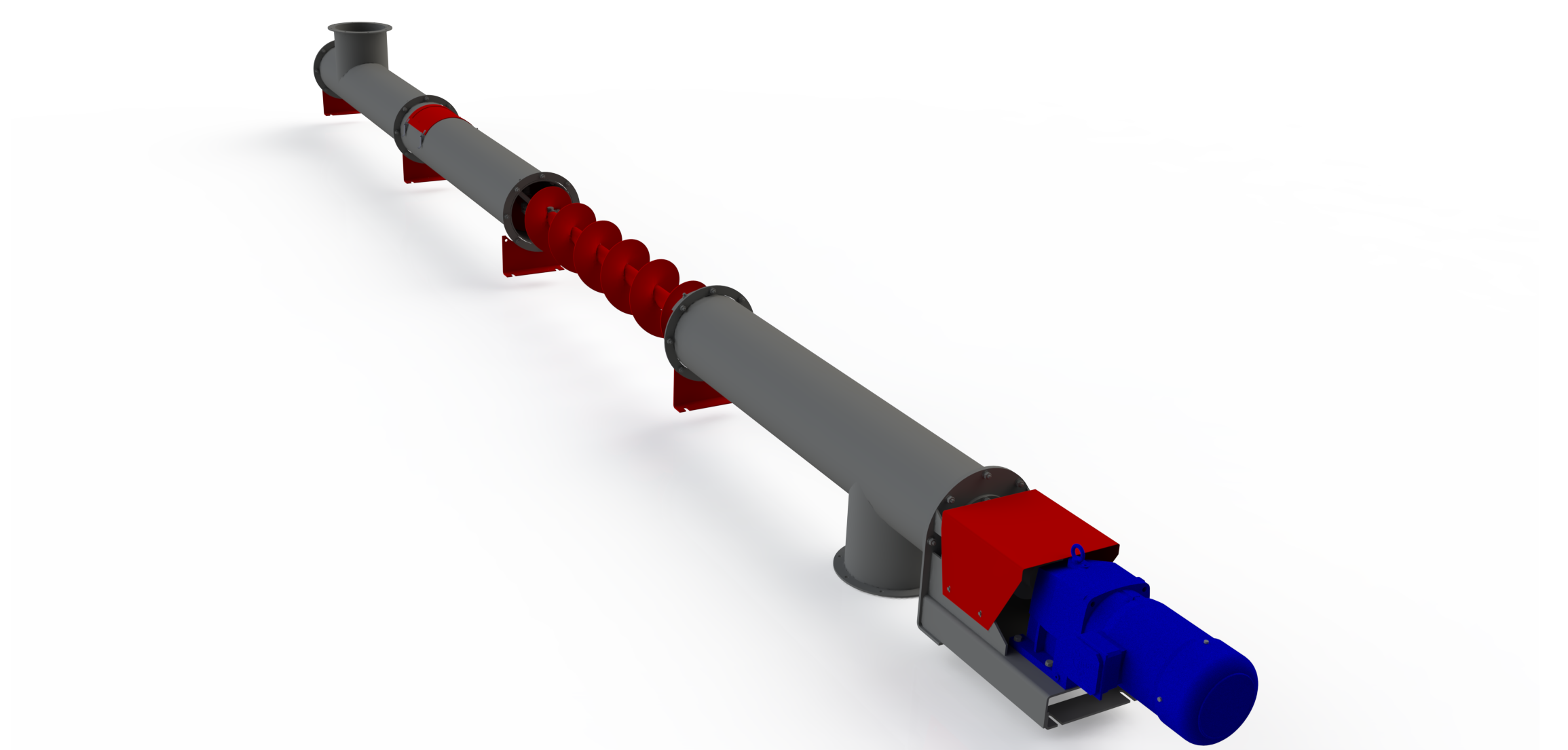

Screw Conveyor

These conveyors are highly popular and are used to move fine-grained or bulk materials horizontally and at various angles.

The design of a screw conveyor consists of a tube or trough containing a large spiral (the auger), loading and unloading points, a drive, and an outlet flange.

It is used to transport bulk products over distances of up to 30 meters.

Screw conveyors come in two main types:

- In a Tube

- In a Trough

Tube conveyors can be horizontal or vertical. They have a modular cylindrical base that can be easily extended or shortened. The modules are connected using intermediate flanges. The auger is supported by additional hangers on longer conveyors.

Trough conveyors are used as an alternative to tube conveyors or when quick access to the auger is needed. Their base consists of a U-shaped trough in which the spiral rotates. These augers are used for heavy bulk goods, such as granulated feed.

The trough is also modular and can be easily extended. Modules are connected with couplings and supported by additional legs. Special seals between sections are used to increase wear resistance.

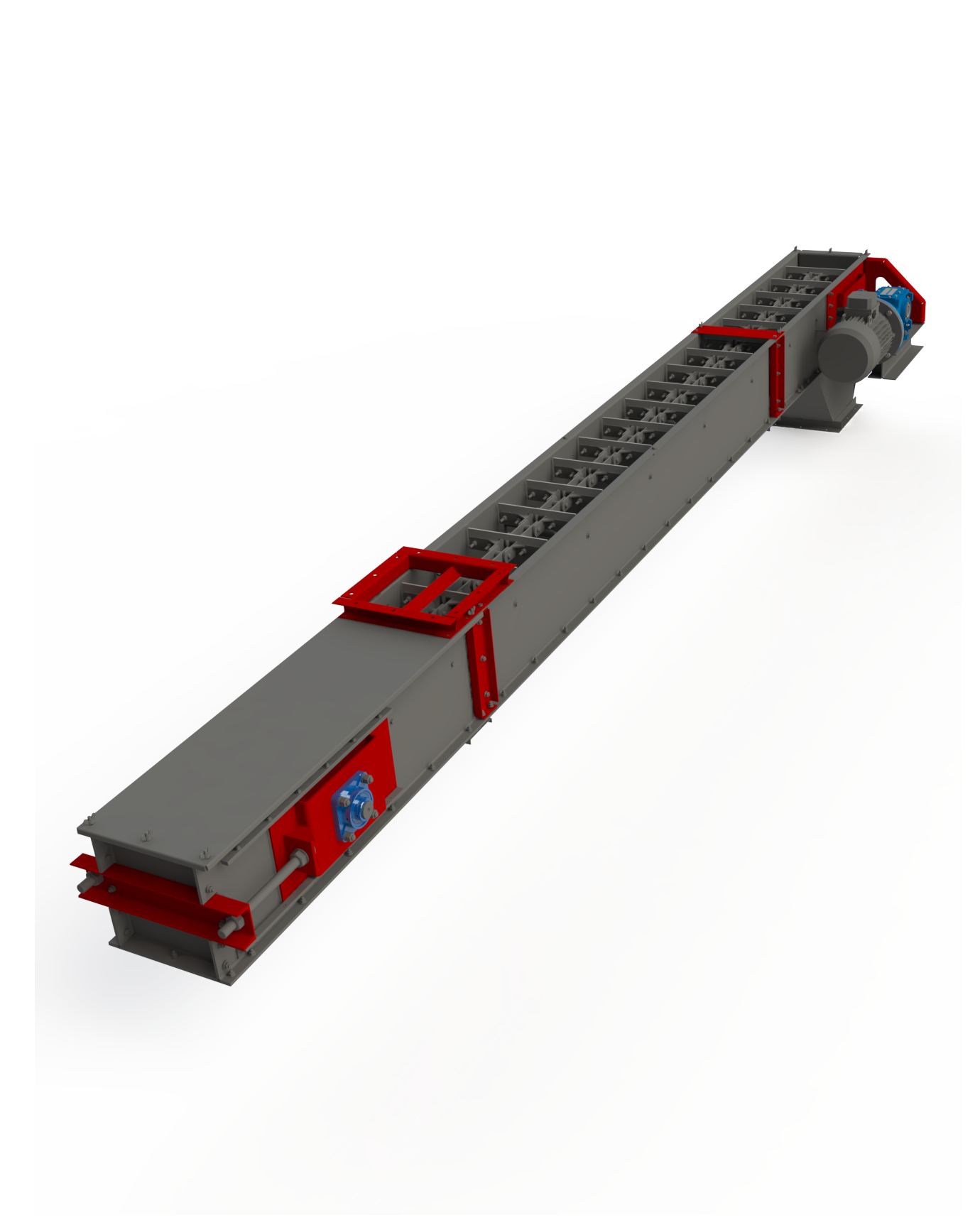

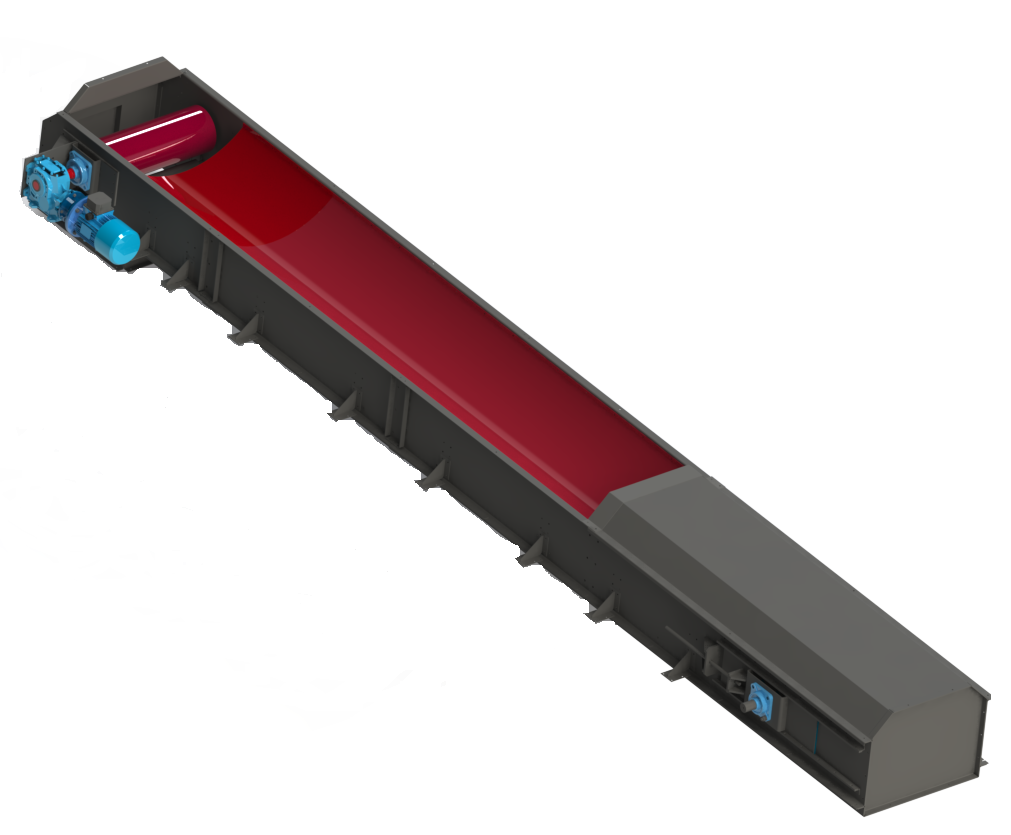

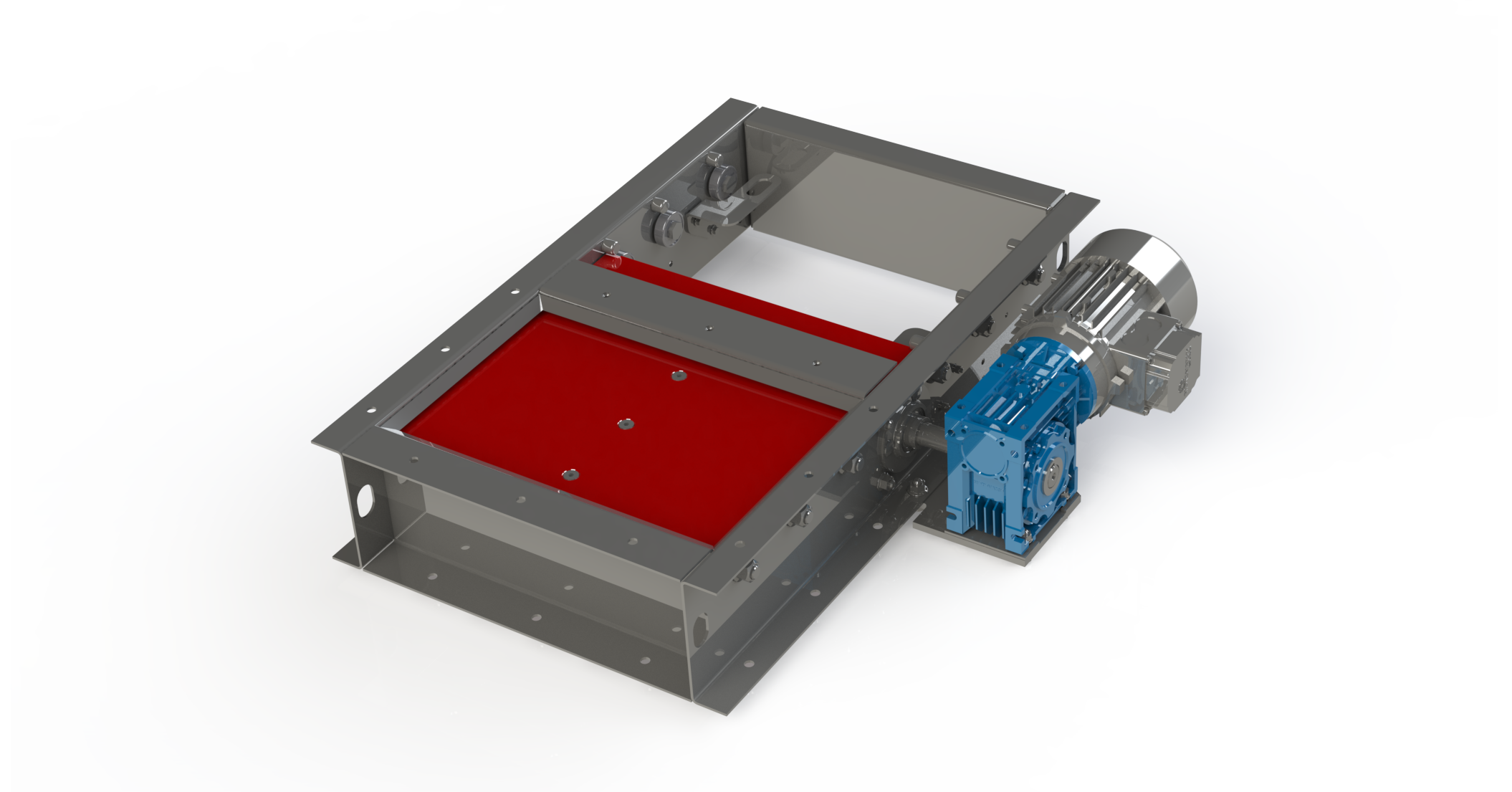

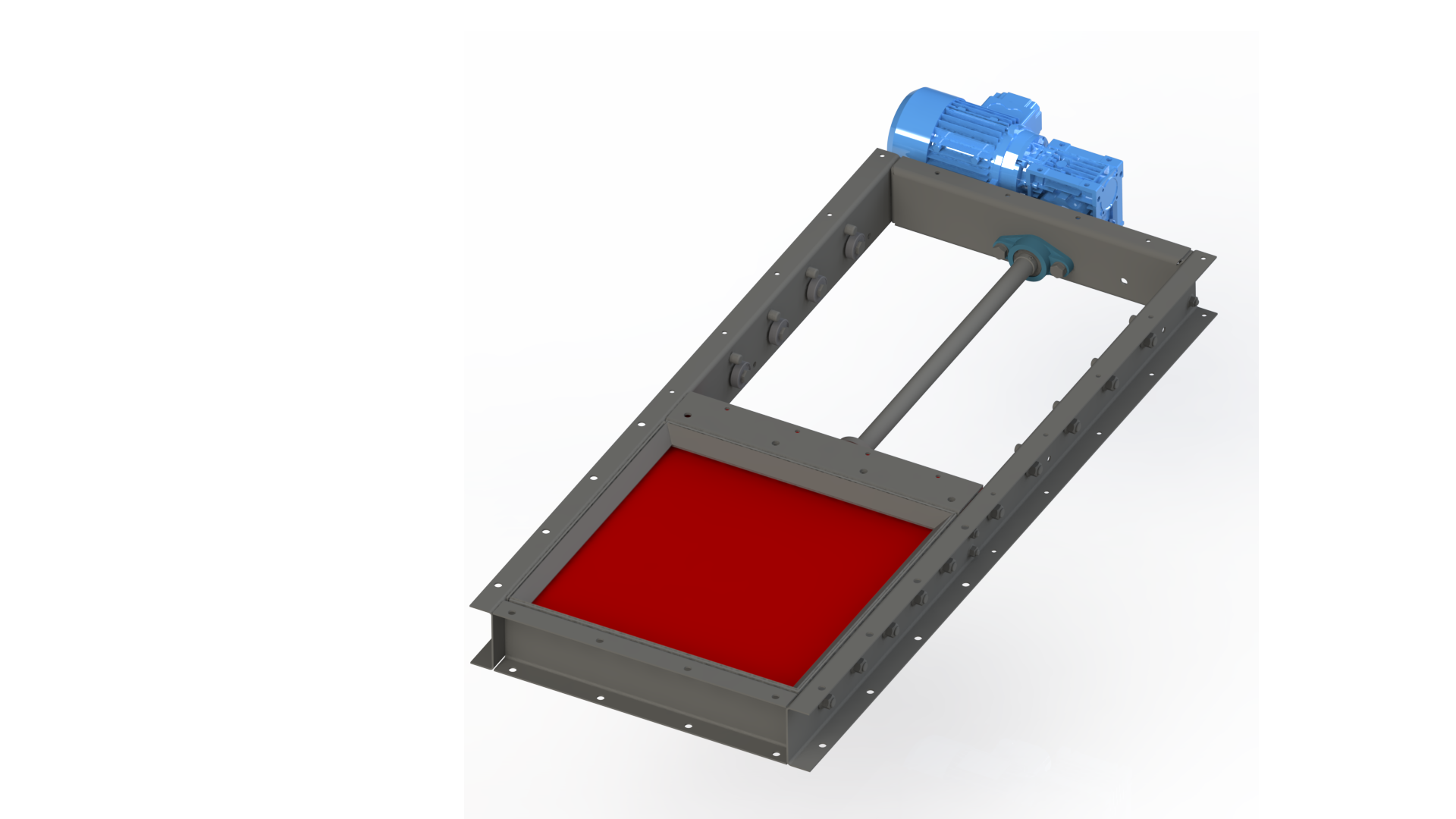

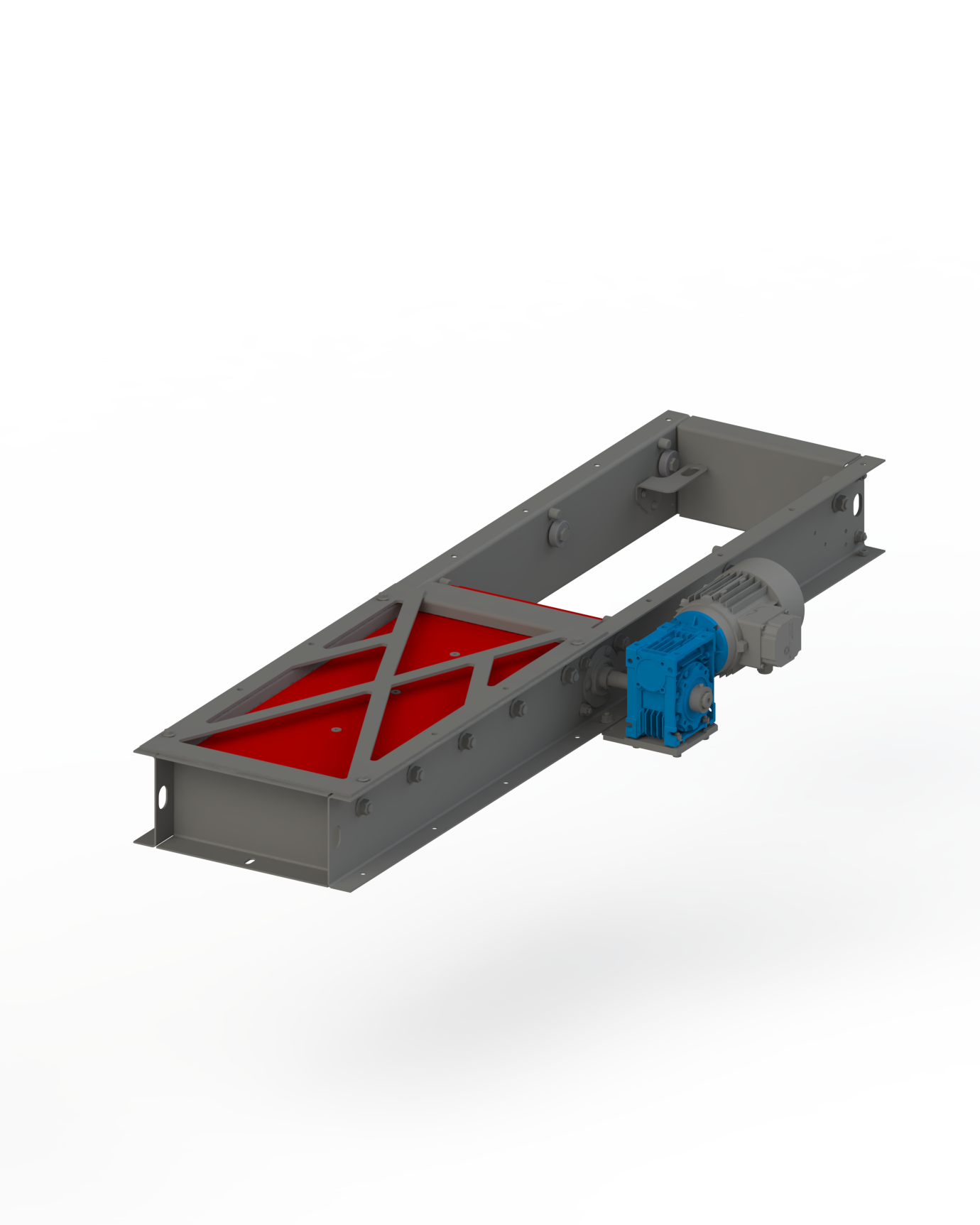

Chain Conveyor

The drag chain conveyor (or scraper conveyor) is designed to move bulk materials horizontally or on an incline (up to 85 degrees) with a very high capacity of up to 600 t/h for grain and over lengths of up to 60 meters.

The basic design of this conveyor consists of a trough with a chain moving inside it, which has scrapers attached. The chain used is typically a plate-link type. The scrapers are made of rubber, polyurethane, or polyethylene.

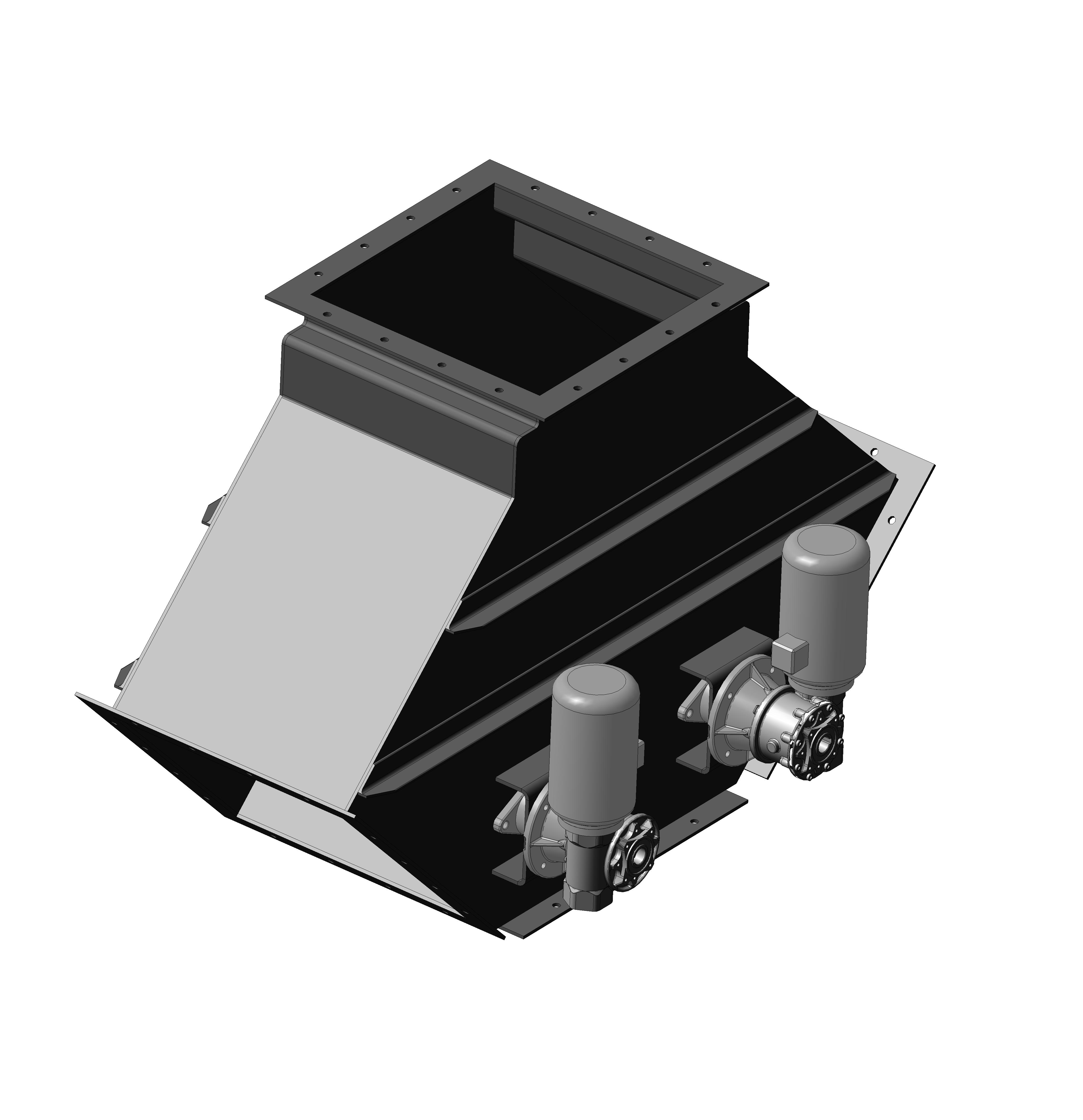

It is often used in conjunction with a loading hopper from a truck or rail receiving pit, transferring materials to another conveyor or a bucket elevator.

Thanks to its simple and versatile design, it is possible to install intermediate discharge and loading points equipped with manual or electric slide gates.

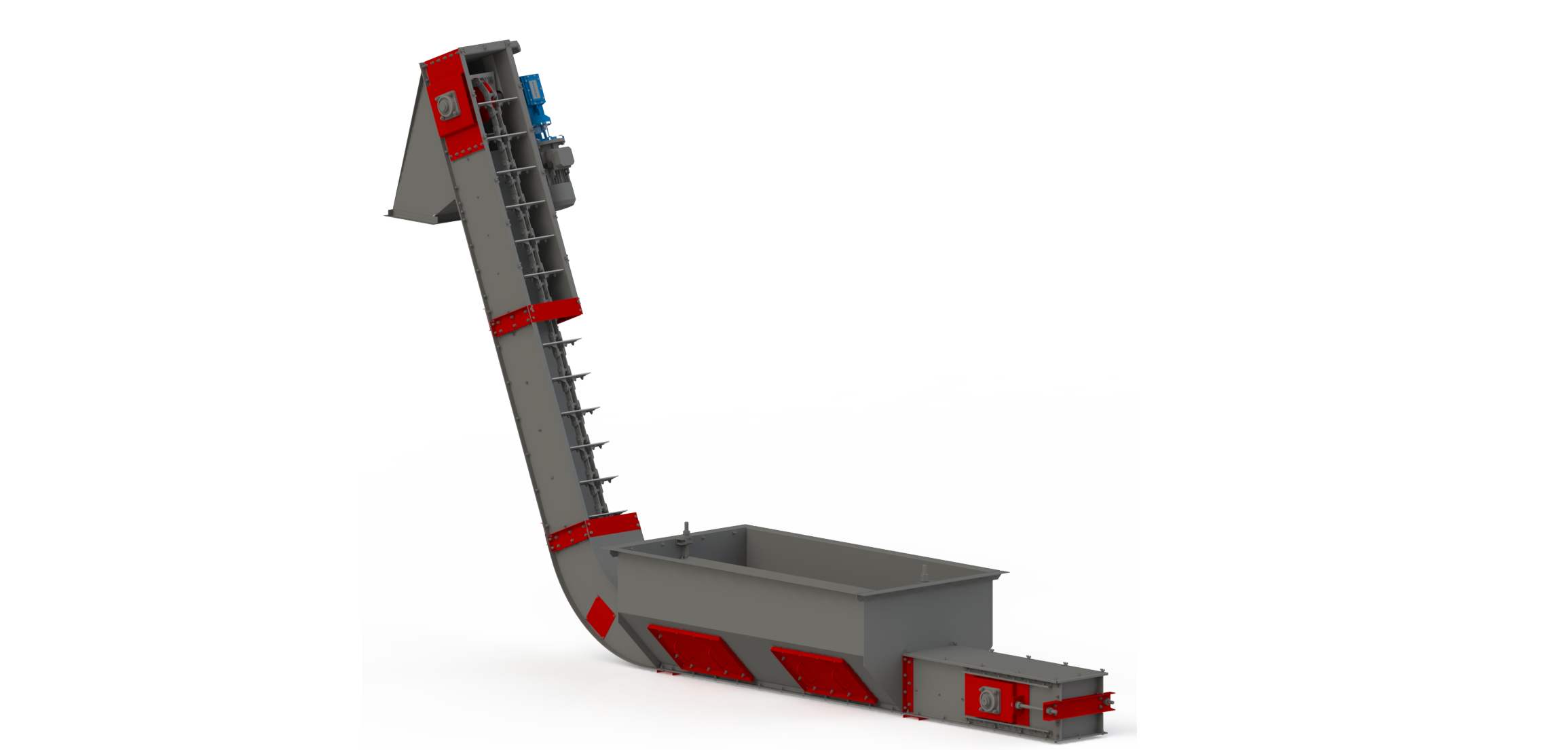

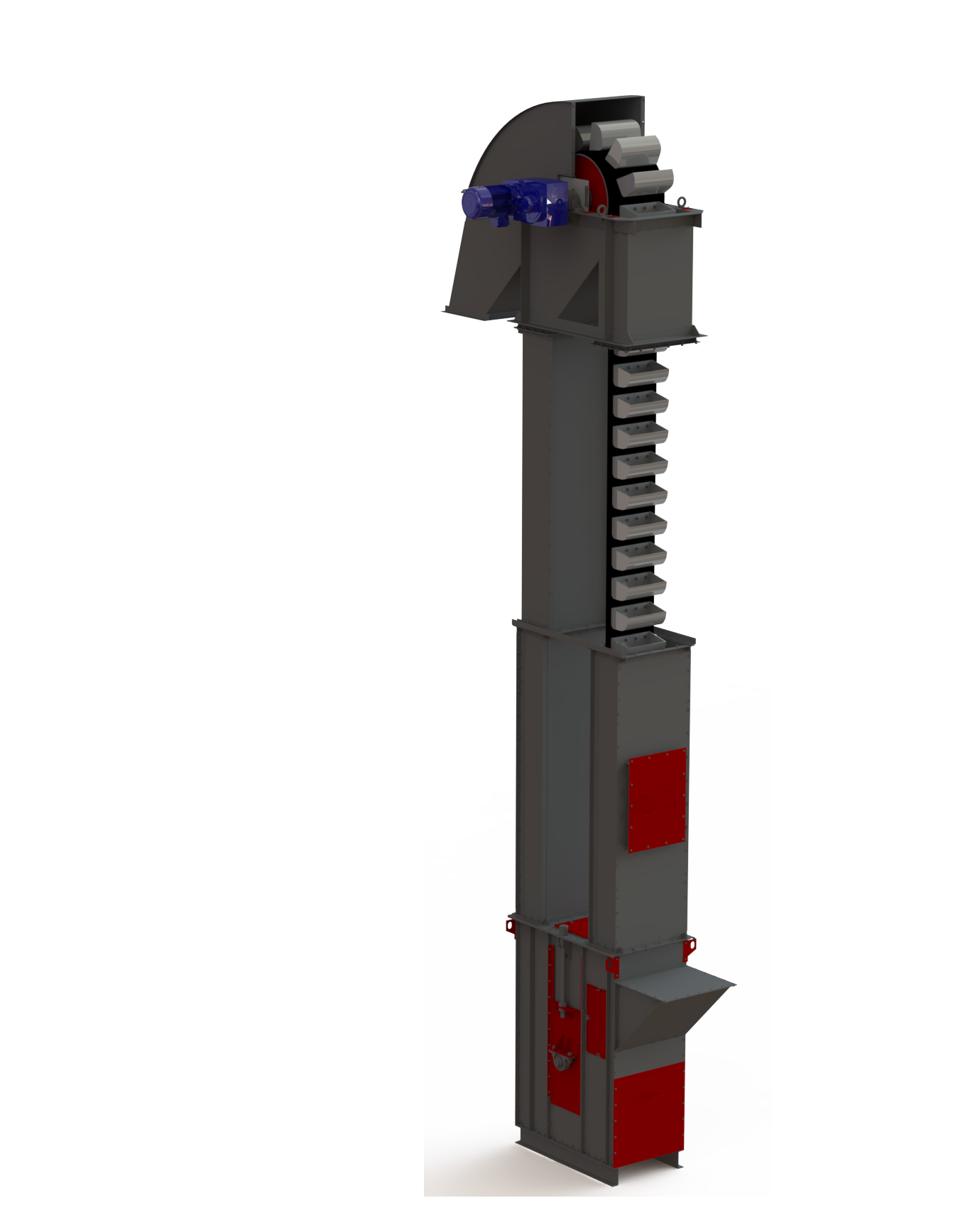

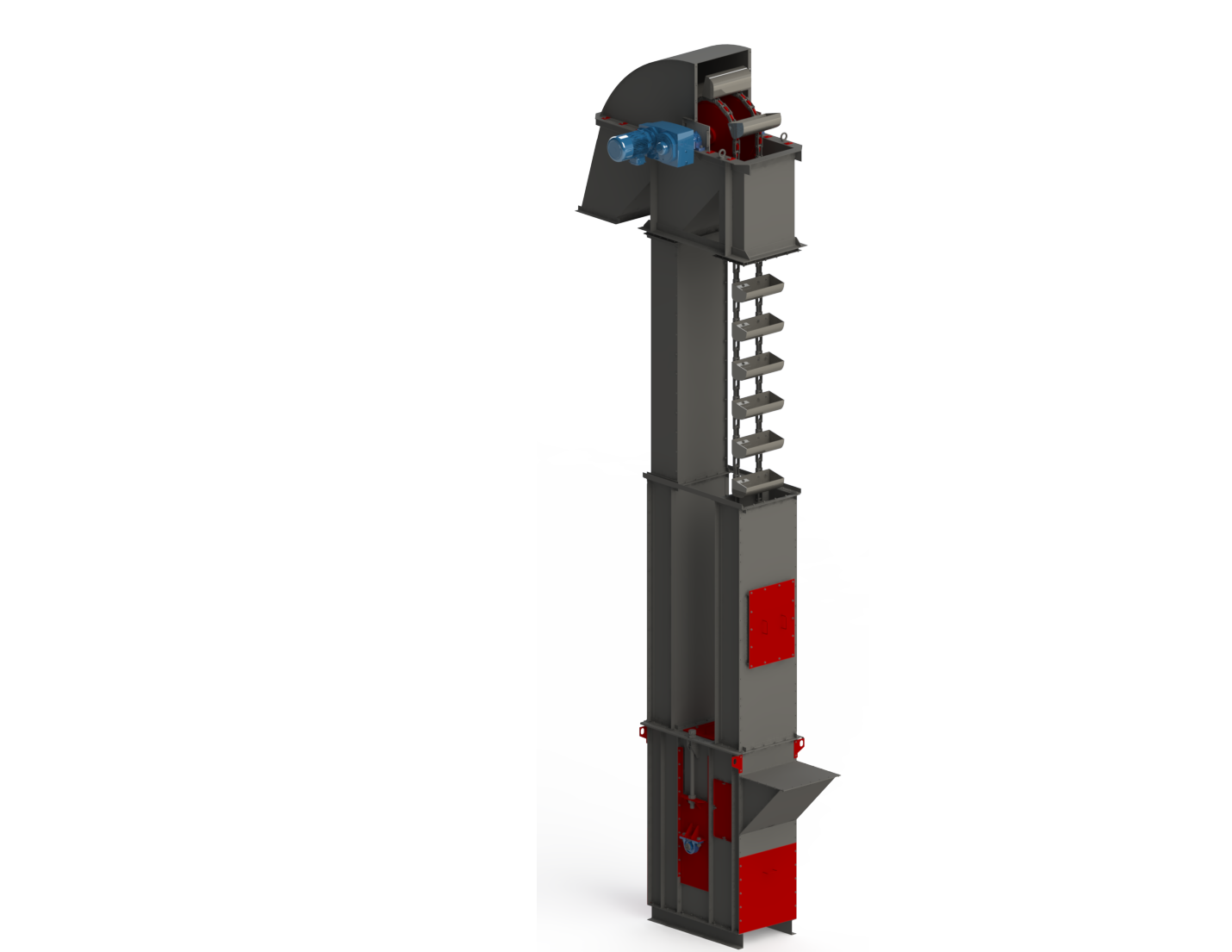

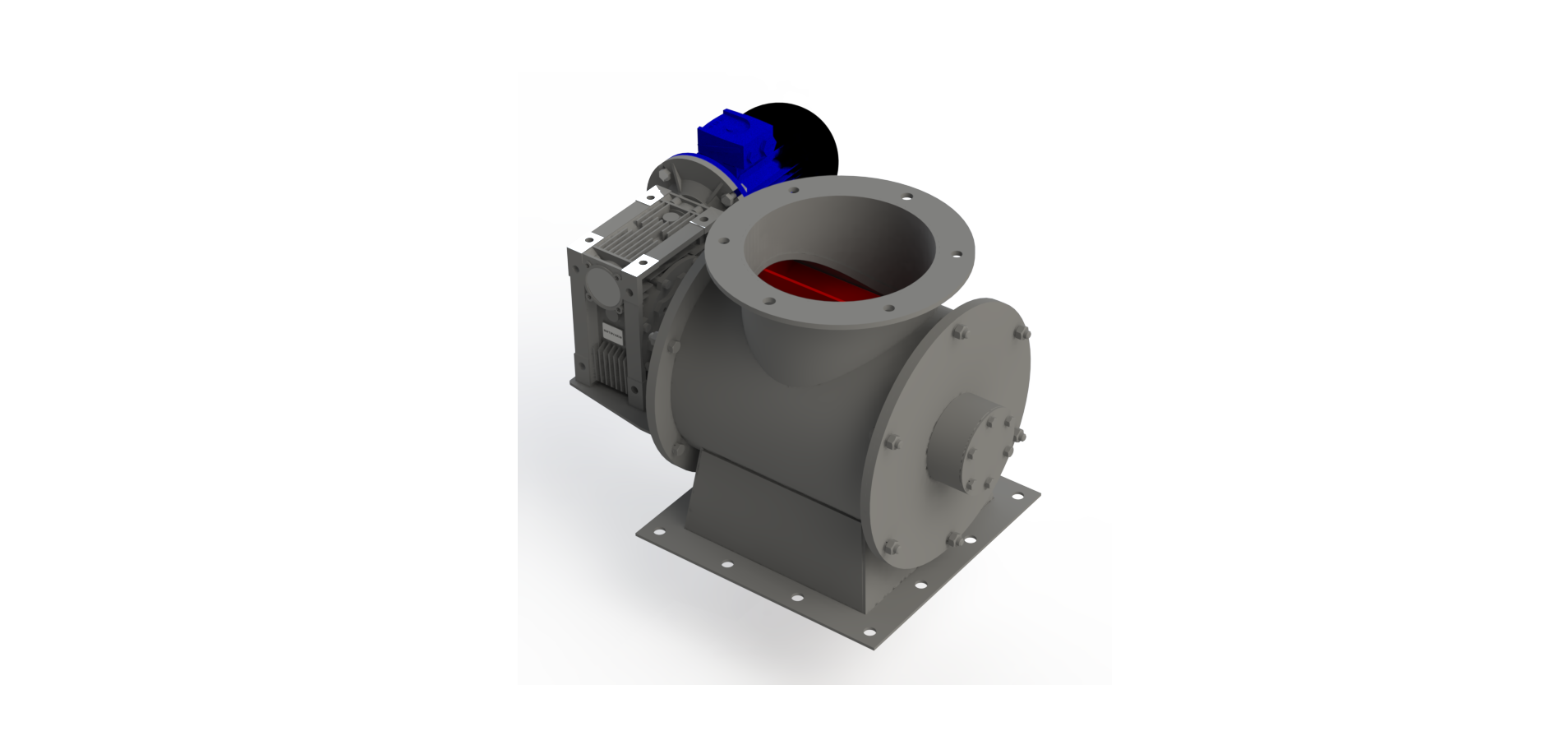

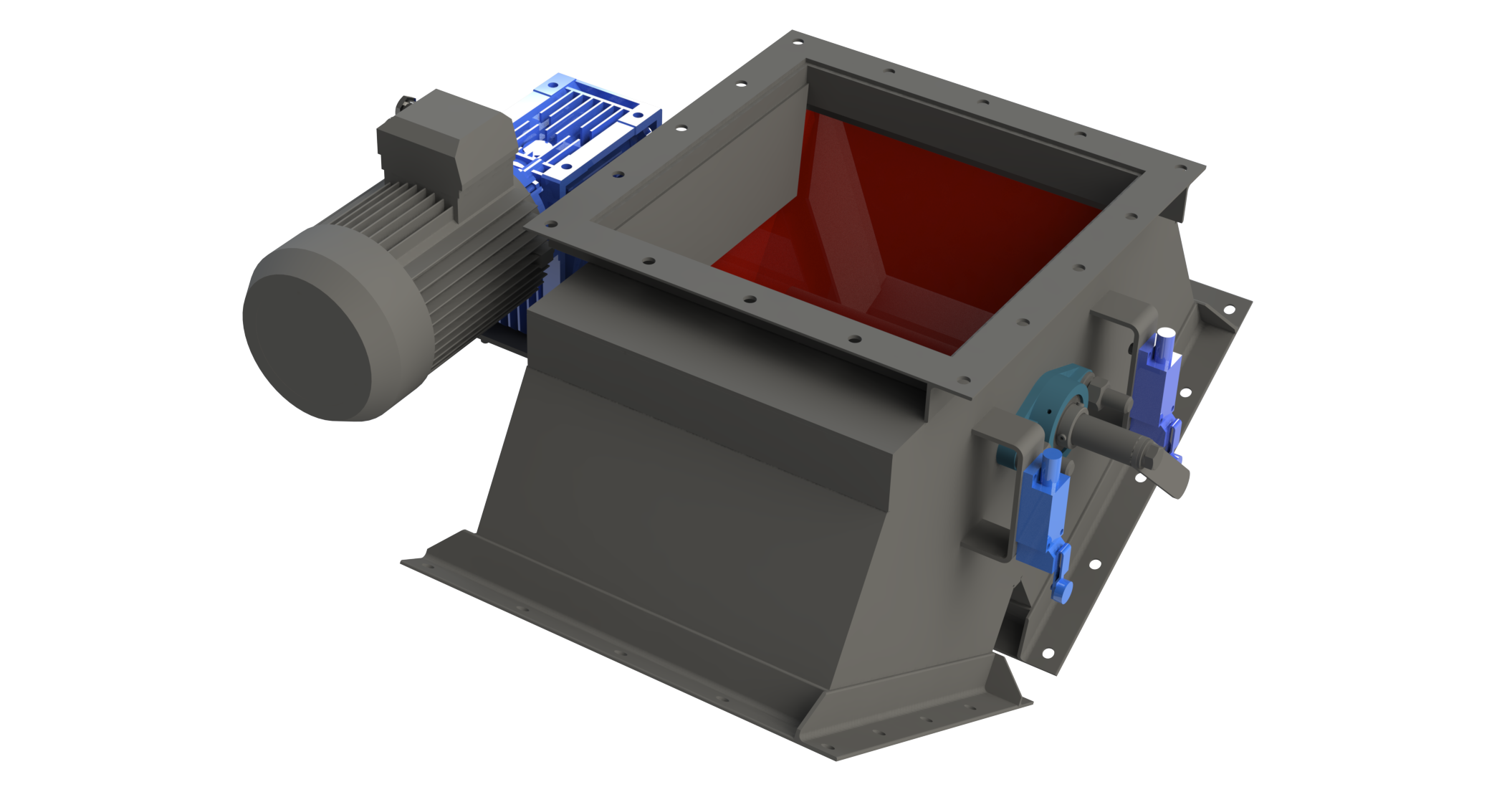

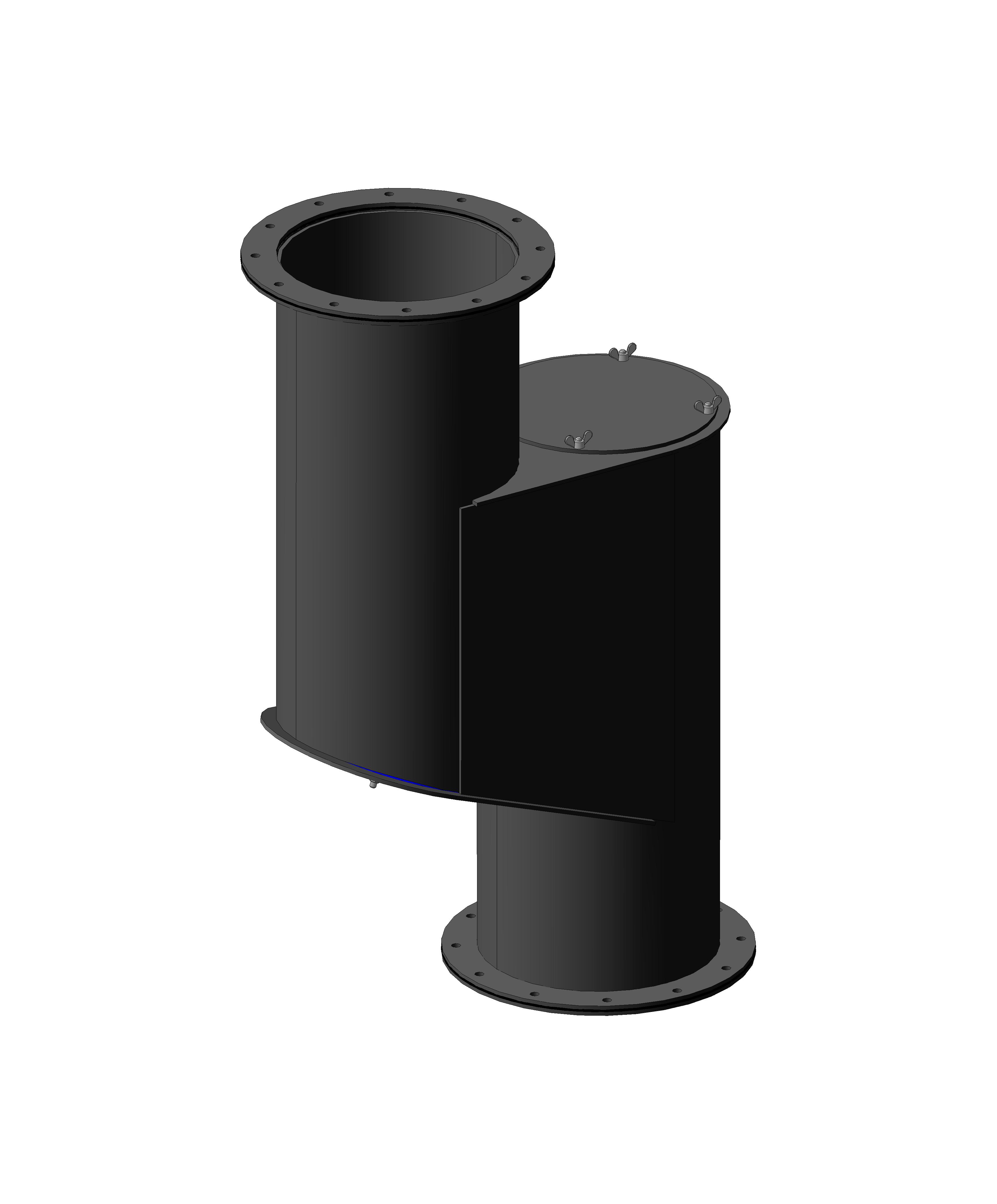

Bucket Elevators (Norias)

A bucket elevator is designed for vertical transport, lifting materials to heights of up to 60 meters. Based on the load-carrying element, they can be either belt or chain types with buckets attached. A self-supporting design with cable guy-wires is also possible.

The structure consists of:

- A loading section (boot).

- A drive station (head).

- Elevator casing (shafts).

Its principle of operation is based on buckets that scoop up material from the boot's inlet. The material is then transported up the casing to the discharge point at the head section.