In production and at enterprises of various profiles, the use of a chain conveyor has become quite common. These conveyors are intended for transportation of loose, heavy goods, for goods with a high temperature level. The productivity of this type of conveyors is quite high compared to a belt type conveyor. For all their bulkiness, they perform their work at a fairly high quality level, therefore, even in spite of their high cost and the care they require, chain conveyors have proven themselves as stably working and wear-resistant units. The most common use of chain conveyors is in elevators, woodworking enterprises, boiler houses (chips, pellets and ash), for fertilizers and other enterprises.

CHAIN CONVEYOR CHARACTERISTICS

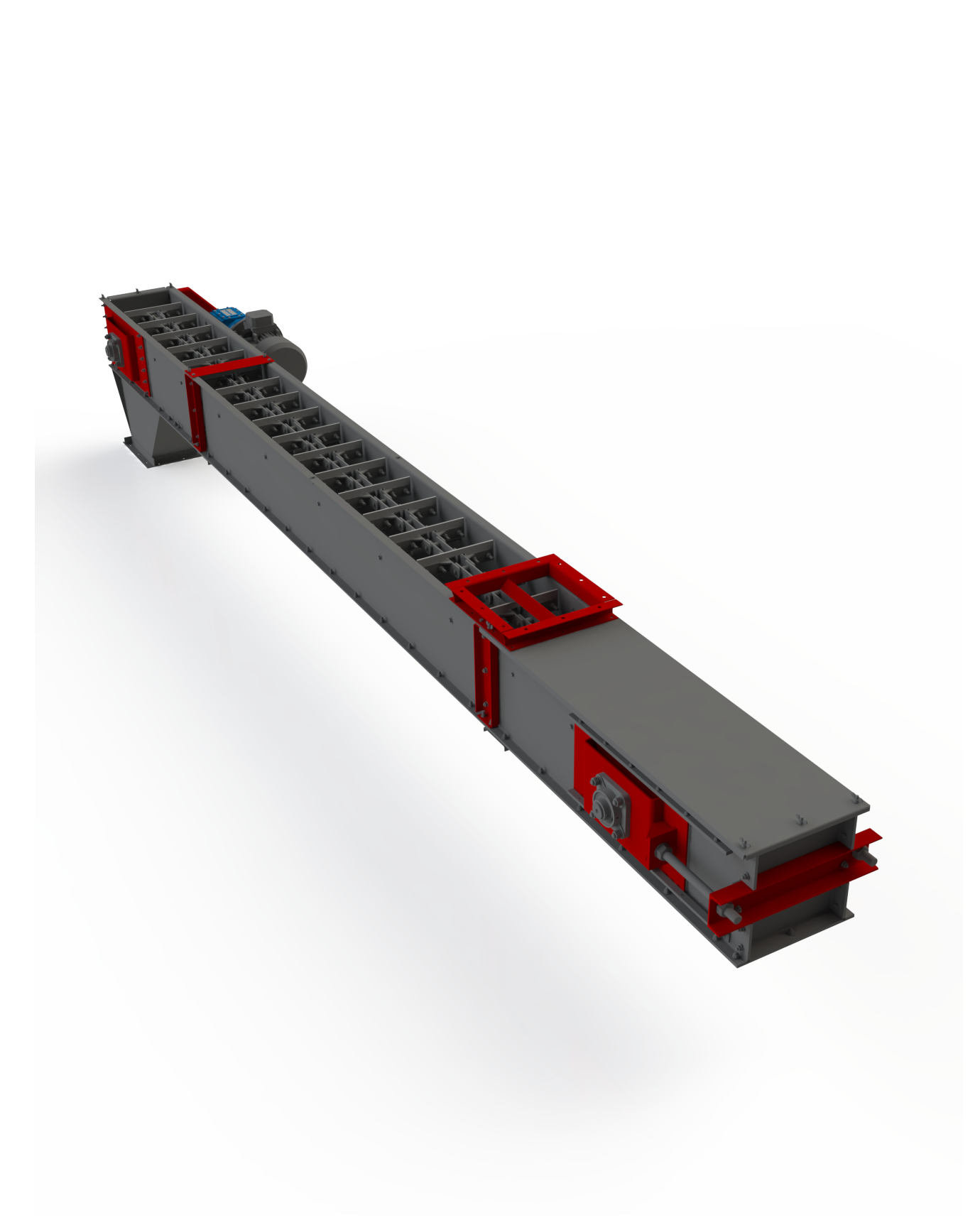

The main thing in the work of this conveyor is that the force here is created with the help of a chain, there can be two or one of them. The conveyor is designed in such a way that it allows loading, moving and subsequent shipment of the moving material. The chain conveyor has the form of a box, inside which a partition or supporting devices can be located. A chain conveyor is constructed from nodes of a typical appearance. The construction of the conveyor has three sections, the leading section, the tensioning section and the intermediate section. The working body of the conveyor is a chain equipped with a special scraper. Chains, depending on the modification of the conveyor, are usually of the plate type. The work of the chain conveyor of the species is carried out at the expense of an electric motor and a reducer. This equipment is located on the frame and is connected using a belt-type transmission or direct. This is how the drive of the chain conveyor is designed. Chain conveyors have many subdivisions into types. It depends on its design features. The conveyor can be cart-type, that is, it has zoning for the transportation of goods.

CHAIN CONVEYOR - OPERATION AND APPLICATION

Let's define some advantages of chain conveyor operation. These include, first of all, the fact that on these conveyors it is possible to set the measured movement of the transported cargo, which prevents it from falling or coming off the conveyor belt. The next important positive aspect is that these types of conveyors are equipped with special devices, such as: anti-slip pads, sides and special limiters. It is also comforting that the device of these units allows you to make settings that specify the route and the amount of cargo being transported. In addition, this type of conveyors is quite ergonomic, which allows you to keep it in rather cramped conditions or rooms with a small area. The conveyor is made of galvanized, structural or stainless steel.